Pump Sand Suction Subsidence Machine Desanding Equipment Bridge

Type Stainless Steel Alloy Metal Material

Introduction

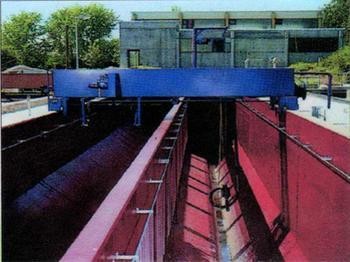

The QX bridge type sand suction machine is mainly used for the sand

water treatment in the aeration grit settling tank of the urban

sewage treatment plant or the water plant, and lifts the large

particles such as gravel and cinder and the sewage mixture that

settle at the bottom into the sand discharge tank beside the pool.

According to user requirements, oil and slag skimming devices can

be added.

| Pool width B(m) | 3 | 4 | 6 | 8 | 10 |

| Gauge Lk(m) | B+0.4 |

| Pool depth H(m) | 3.0~7.0 According to the user's requirements |

| Pool length L(m) | According to the user's requirements |

| wheel-base L1(mm) | 1500 | 1800 | 2000 |

| Running speed v(m/min) | 1.5~2.0 |

| Walking motor power N(KW) | 0.37 | 2x0.25 | 2x0.37 |

| Submersible sewage pump | handling capacity Q (m3/h) | 20 | 30 |

| Head of delivery h(m) | 2.0 |

| Capacity N2(KW) | 0.75 | 1.10 |

| Number of submersible sewage pumps | 1 | 2 |

| Steel wheel diameter d(mm) | 250 |

| Rail specification(kg/m) | 15(GB/T11246-1989) |

| Wheel-pressure P(KN) | 10 | 14 |

Structure and Working Principle

The equipment adopts mobile bridge type and pump suction type. When

the sand suction machine is not working, it stops at the water

inlet; when the sand suction machine is working, the driving is

under the instruction of electrical control. Slag board, scrape the

scum and skim it into the steel skimmer tank at the end of the

pool; when driving in the reverse direction, the skimmer rake lifts

and leaves the liquid surface to prevent the scum from going

backwards; the sand at the bottom of the pool is drained by the

sand suction pump through the suction pipe Into the sand collection

tank by the pool, and then flow into the sand-water separator

through the pipeline, and proceed to the next step of processing.

According to this, the reciprocating movement is performed to

achieve the purpose of sand absorption, sand discharge, and slag

skimming.

Main Features

1. Reciprocating sand suction and slag skimming, high efficiency

and simple structure.

2. The vortex low-lift submersible pump is used to suck sand, no

water diversion operation is required, no blockage, wear-resistant,

safe and reliable.

3. One-way skimming makes the pool surface cleaner.

4. After the grit is aerated and circulated, the organic matter on

the sand has been washed, and the discharged sand has no odor.

5. The equipment is easy to operate, and the operation of the

equipment can be directly controlled locally/remotely.

Main Parameters and Installation Size Chart

Outline and Installation Chart

Packing and Delivery

1. Waterproof packing with the international export standard by

20ft, 40ft, 40hp container. Equipment Fittings, Electric Motor and

Power Cabinet will be packed in Wooden Case or Iron Box. Other

Equipment will be packed by Color-Stripes Plastic Cloth.

2. The whole plant machinery size are large as normal, so we will

use Waterproof cloth to pack all of them. The motor, gear box or

other easily damaged parts, we will put them into box. We have a

professional shipping department, they will try their best to save

your container quantity.

Why Choose Us?

1. Longdai has more than 10 years of experience in wastewater and sludge treatment.

2. We introduce German technology, thus our product is much better than other Chinese manufacturers.

3. We only use the best parts from best supplier.

4. We have our own R&D center and complete manufacture system.

About Us

Located in Yixing, an advanced and beautiful city of Jiangsu

Province, China, Longdai Co., Ltd is a processing equipment

supplier of petrochemical industry specialized in environmental

processing &integrating independent research and development,

design, general contracting, environmental protection equipment

manufacturing, and relevant material supply.

FAQ:

Q: Are You Trading Company Or Manufacture?

A: We Are Both Manufacture And Trading Company. We Have Over 30

Years' Professional Experience As a Waste Water Treatment Equipment

Manufacturer And Engineering Service Enterprise.

Q : What Are Your Main Products?

A:Keywords :Sludge Dewatering Machine Equipment, Screw Type Sludge

Dewatering Press Sludge Screw Press, Dewatering Sludge Machine

Screw Press ,Sewage Treatment Equipment ,Sludge Treatment

Plant,Screw Press Sludge Dewatering ,Dewatering Sludge,Dewatering

Machine For Sludge, Dewatering Sludge Machine Screw Press, Rotary

Drum Bar Screens, Equipment DAF, DAF Price ,Dissolved Air Flotation

System Price, Sludge Shaftless Screw Conveyor,Chemical Dosing

Device ,MBBR Price,MBBR Media,Disc Diffuser, Polymer Preparation

Chemical Dosing System, and other customized machines.

Q: How Can I Find The Suitable Model?

A: Please Provide Flow Rate, Solids Content And Sludge Type, or

directly contact us by the clicking the “contact” icon. We Can

Assist You In Model Selection.