Jiangsu Longdai Environmental Technology

Co., Ltd. is an environmental protection equipment manufacturer

with more than 15 years of experience. It has provided a large

number of sophisticated environmental protection equipment at home

and abroad, established three branches in China, and cooperated

with many universities to build Longdai R&D center. There are 4

middle doctors, 10 masters, and 25 senior engineers.

Main business: "Petrochemical Wastewater Treatment, Urban and Rural Wastewater

Treatment, Waste Gas Collection and Treatment, Industrial

Wastewater Treatment, etc."

Main equipment: "Integrated treatment equipment, grille decontamination machine,

sand water separator, mud scraper, air flotation device, dosing

device, sludge thickener, rotary drum micro filter, conveyor,Manual

and Mechnical Bar Screen ,Bridge Scrapers ,Ordor Control

System,Belt/Screw Conveyor,Disc Filter etc."

Work follows 5 principles:

1.Sales

The sales team keeps abreast of market

prices and provides customers with the most accurate and most

favorable quotations.

2.design

The technical team participates in

technical exchange meetings every year, exchanges experience with

professionals, continuously improves technical competitiveness, and

provides customers with the clearest and most practical design

solutions.

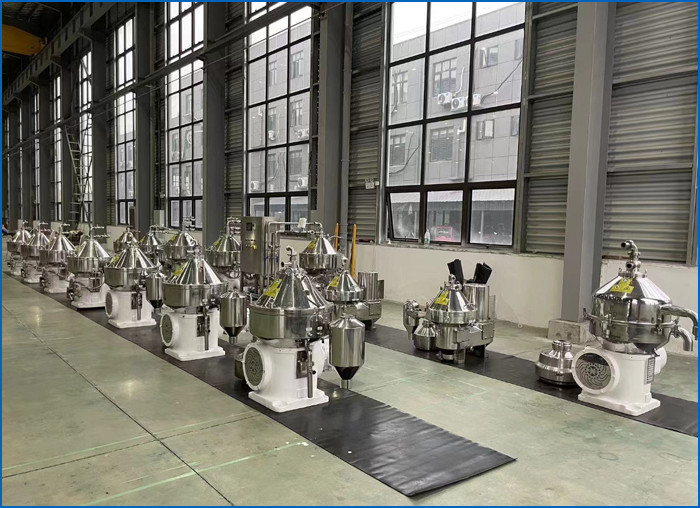

3.manufacture

The processing team controls the

manufacturing details of each equipment, and manufactures the most

sophisticated and reliable equipment for customers.

4.transportation

The transportation team has been to

every corner at home and abroad, and has never made any mistakes,

planning the best route, and transporting equipment for customers

is the fastest and safest.

5.quality

The company has passed ISO9001-2008

international standard quality system certification.

We look forward to contacting you,

please give us a chance. I hope we can trust each other for mutual

benefit and win-win results.

Best wishes.

---------------------------------------------------------------

The following is our company's

information:

Jiangsu Longdai Environmental Protection

Technology Co., Ltd.

Phone: 0510-87837699

Fax: 0510-87837599

Chinese website: www.zgldhb.com

Foreign language website:

http://www.longdaiwwt.com/

Email: longdaicompany@126.com

Address: No. 20, Chengwen Road, Gaocheng

Town, Yixing City

Zip code: 214214